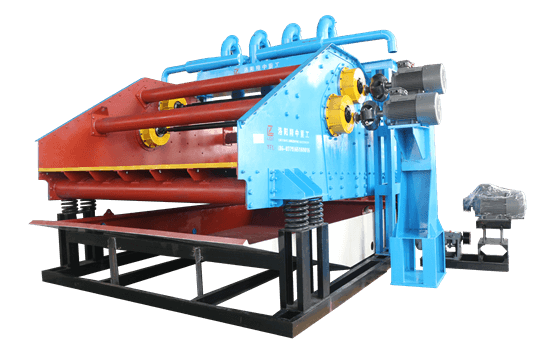

GP series tailing recovery screening machine is specially designed for metal tailing recovery, which combines with the characteristics of metal tailing on the basis of GZ series high frequency sieve. It is mainly used for iron ore, copper, gold and aluminum ore tailing dehydration. It is a new type tailing recovery machine which is designed to focus on solving problems existing in many tailing recovery screening machines in domestic.

GP series tailing recovery screening machine has features such as simple structure, low cost, high efficiency, low consumption, low noise and easy maintenance, etc.

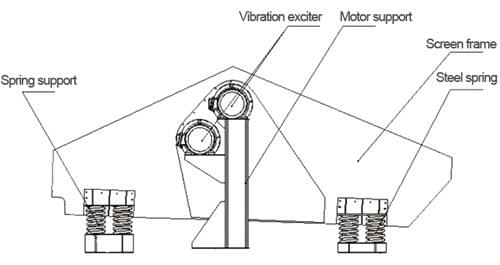

1. High efficiency, strong vibrating force and large capacity.

2. Simple structure and easy operation and maintenance.

3. 45°angle install increases the dewatering area.

4. Vibrating frequency is adjustable to meet different ores.

5. Torsional shear type high strength bolts are used between side plates and beam. No weld gap avoids side plates cracking during vibrating.

6. Polyurethane screen with better elasticity and less blocks. The PU side push plates protect the equipment from the rushing material and guard the long life of the whole device.

GP series mine tailing screen is driven by two vibrating motors, which make the screen sieve move to-and-for on line to achieve the filtering purpose. With the vibration of the screen, the concentrated tailing materials are continuously threw up and down on the screen, and the materials are loosen and crashed to the sieve, the small size materials are filtered away from the sieve holes.

Finally it reaches the aim of classifying, dehydrating and desliming.

| Model | Capacity (t/h) | Screen Panel (mm) | Hydrocyclone (mm) | Power (kw) | Overall Size (mm) |

| GP12-30 | 20-50 | 1200*2400 | 150*2 | 11 | 4280*2600*3000 |

| GP15-60 | 60-100 | 1500*3000 | 150*4 | 22 | 4880*2900*3280 |

| GP18-90 | 80-140 | 1800*4200 | 150*6 | 37 | 6080*3200*3500 |

| GP24-120 | 120-200 | 2400*4800 | 150*8 | 44 | 6680*3800*3800 |

All product information including pictures, types, data, performance, specifications on this website is for your reference only. Adjustment of above-mentioned contents may take place. You can refer to the real products and product manuals for some specific messages. Except the special explanation, data interpretation right involved in this website is owned by LZZG.

Inquiry